Rapid Production

The application of the rapid prototyping device will be to merge rapid prototyping capabilities with the high-volume output of conventional manufacturing.

It is believed that the rapid manufacturing processes may soon lead to the tooless production of finished goods and the mass production of individually customized parts.

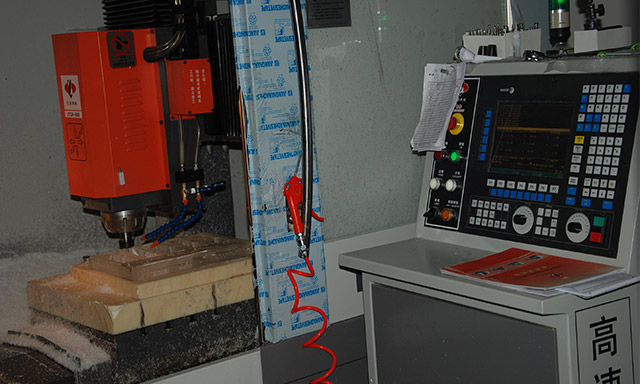

Rapid Tooling

Rapid Tooling(RT) describes a process that is the result of combining Rapid Prototyping techniques with conventional tooling practices to produce a mold quickly or parts of a functional model from CAD data in less time and at a lower cost relative to traditional machining methods.

Plastic Injection Molding

At 101, we product high quality custom plastic Injection molding. Some of them is to make defense, medical, aerospace, automotive and consumer products.

Rapid injection molding(prototype injection molding) is a fast and economical way for injection moling companies to get real injection molded parts for prototyping, initial runs, and low-volume production. We turn a 3D CAD model into fully functional parts and provide the quickest turnaround time at low prices.

When production volumes are moderate, rapid injection molding can be a complete, cost-effective production solution. Rapid injection molding enables companies to experiment and perform functional tests with real parts without worrying about cost overruns of rising design costs.

Our prototype injection molding process allows us to create molds for simple to complex parts, in short lead times and with attractive costs. Prototype injection molded parts are ideal for one-off to hundreds of parts. For most prototype injection molded parts. 101 uses low-cost soft tool steel or aluminum to make the core, cavity, and ejector plates, then inserts these into a Master Unit Die(MUD) base.

Rapid injection molding can be used as bridge tooling, to produce fully functional production parts until the steel tool is available.

Very Low Volume Production Injection Molded Parts From 10 to 1000 injection molded parts For Prototype Molds we typically use soft tool steel or aluminum to make a complete standalone mold. We can add custom cooling circuits, hot tips, and other refinements to aid with the production of technical resins or complex geometries. For polished or high-gloss parts, we use the polishing stainless steel. This process offers medium tooling and part price.

Low volume Production Injection Molded parts From 1000 to 100,000 injection molded parts For Pilot Production molds we typically use pre-toughened, high-quality tool steel or stainless tool steel to make a complete mold. This process incurs a higher tooling cost, but a much lower part cost.

Full Production Injection Mold tools These are full production injection mold tools that will be exported outside China for our customers to rn is their own facilities or at a local molders. Molds are to full USA/western standards. Open and shut, multi slide, unscrewing etc. are all available. If you have a requirement for full production molds where the molds will be exported to you, contact our PM team.