Vacumm Castings

Vacuum casting is a casting process for elastomers using a vacuum to draw the liquid material into the mold. This process is used when air entrapment is a problem, there are intricate details or undercuts, of if the material is fiber or wire reinforced.

Vacuum casting is a low-cost but reliable method for making a small number of high-quality prototypes based on a master model.

The tolerance of vacuum cast parts is dependent on the accuracy of the master model, part geometr and casting material. Generally, ashrinkage rate of 0.15% is normal.

Advantages Of Vacuum Casting

|

Vacuum casting is an ideal choice for rapid prototyping because: |  |

|

There is a low initial cost since it doesn't require investment in tooling | |

|

The high fidelity of the mold gives excellent surface details requiring little or no post-process | |

|

Many different molding polymers are available that can be pigmented to meet your color requirements | |

|

Molds can be read in a rew days once the master model has been created | |

|

Molds are durable up to approximately 50 copies so it's great if you need more than one copy | |

|

We provide overmoling, so that different types and hardnesses of plastic can be molded together into a single unit | |

|

It is an excellent option for testing multiple variations of a prototype design for rapid product development |

The Vacuum Casting material

The Vacuum Casting material include ABS, PP, Acetal, Crystal Clear, Rigid PA POM, Rubber, High-Temp ABS, etc.

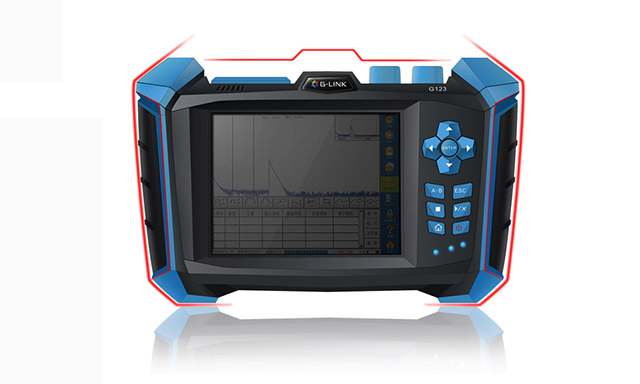

Rapid Production

The application of the rapid prototyping device will be to merge rapid prototyping capabilities with the high-volume output of conventional manufacturing.

It is believed that the rapid manufacturing processes may soon lead to the tooless production of finished goods and the mass production of individually customized parts.

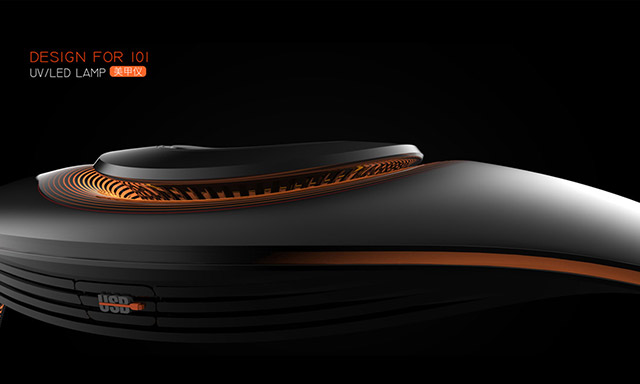

Rapid Tooling

Rapid Tooling(RT) describes a process that is the result of combining Rapid Prototyping techniques with conventional tooling practices to produce a mold quickly or parts of a functional model from CAD data in less time and at a lower cost relative to traditional machining methods.