The general idea of product waterproof structure design

The general idea of product waterproof structure design

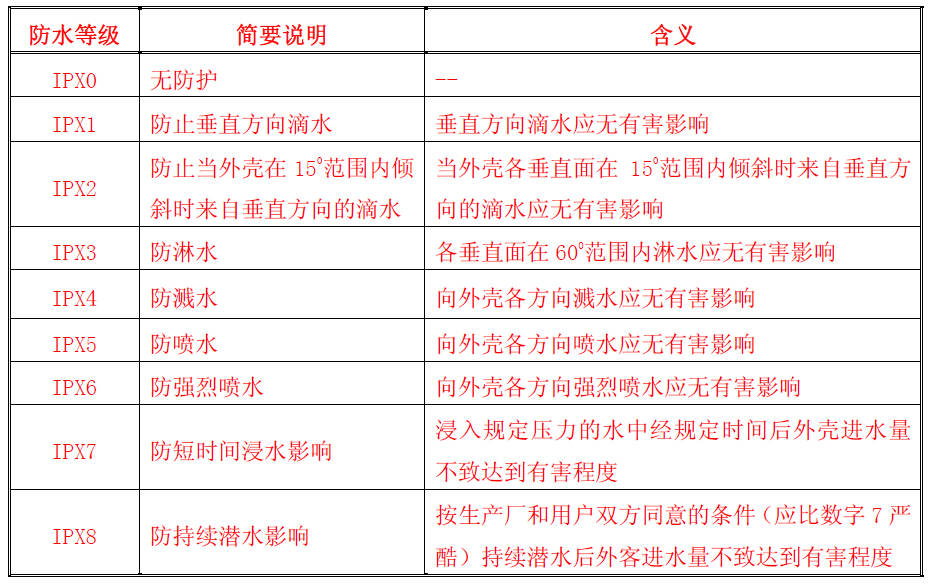

Before discussing waterproof structure design, let's take a look at the standards of dustproof and waterproof:.

Waterproof most products are mainly upper and lower shell waterproof, button waterproof, battery door waterproof, sensor lead part waterproof, commonly used waterproof methods are mainly glue, ultrasonic, two beer plastic, beer inlay, install O-ring.The main reasons for poor waterproof plastic deformation;Water protection is not a line;O-ring preloading is too loose or too tight;Structural stiffness is not enough;Screw distribution is not uniform or slippery teeth, etc.

First, the disadvantages of plastic deformation are obvious, and there are many ways to prevent deformation, such as improving the glue mouth, changing the transport of water, strengthening the bone, increasing the demould slope and so on.For some products, the main reason for the deformation is due to the appearance of the shell before and after the surface of the type, or the internal space is too small to lead to the thickness of the plastic wall changes caused by production.

Two, the water is not on the same surface, the O-ring placed on the surface is irregular curved surface, when the upper and lower cover shell waterproof line is not easy to coherent, such waterproof effect is not good.Similar shape of ultrasonic treatment effect is not good, should be avoided as far as possible.To ensure that the waterproof line is coherent, should try to make the waterproof line is a single - shape plane with a single plane (or surface) intersection.

Uneven screw distribution or slip teeth. Uneven screw distribution will lead to too loose or too tight prepressing of the O-ring. Locally loose O-ring is certainly not waterproof, but the tighter the better.

Four, the lead wire part is waterproof.Because some electrical components lead wire to another processing in the connection with the circuit board, such a structure can be used in the box-type structure, not only will need to waterproof parts of the components were assembled, and then cover several parts together.

Therefore, the waterproof structure design of the product should be designed in strict accordance with the relevant national standards. In addition, in the design of different products, we need to consider more reasonable waterproof design methods.